Profiled steel grid

-

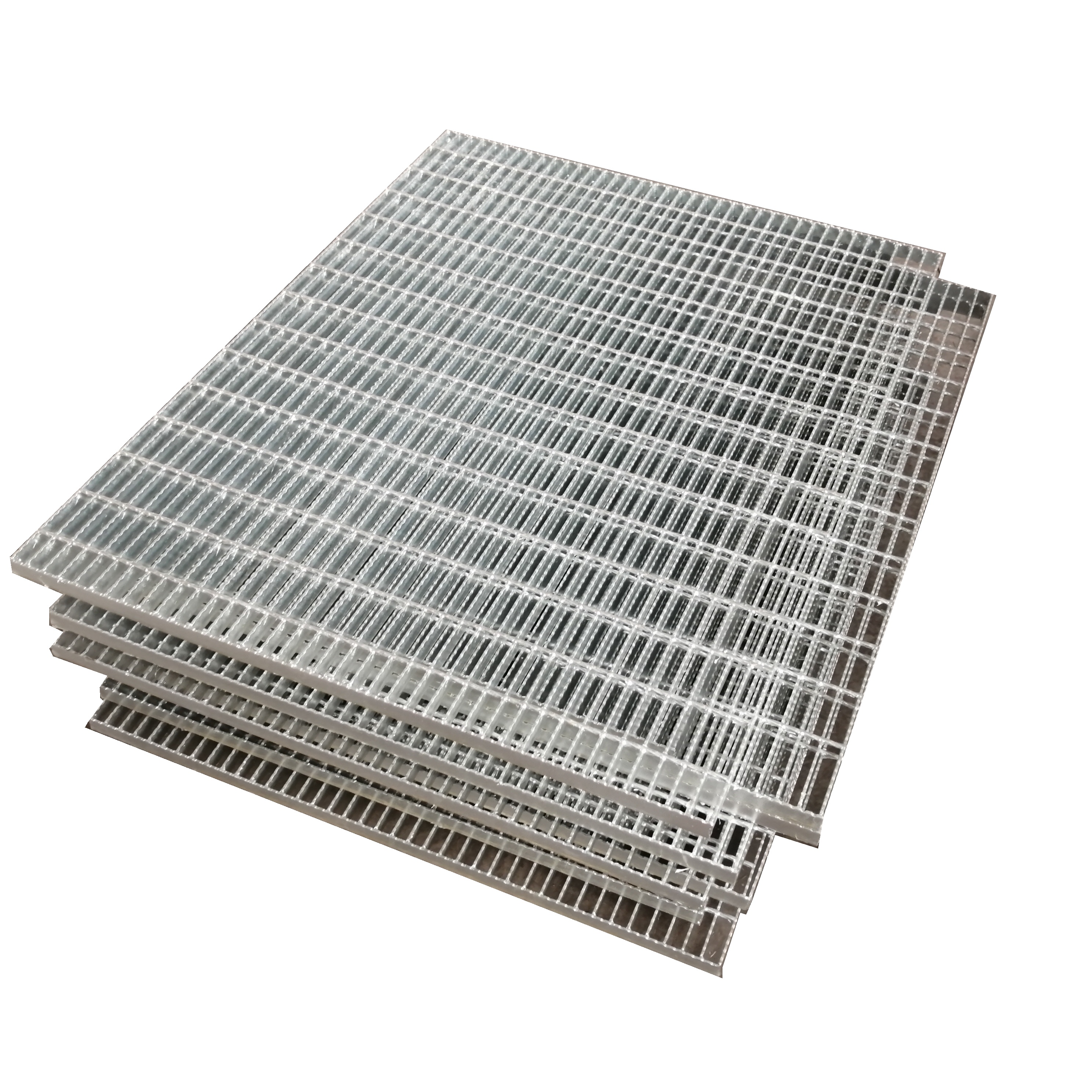

30×30 30x3mm Ss Trench Grating Metal Plates For Driveways

Overview Quick Details Warranty: 1 Year After-sale Service: Online technical support, Return and Replacement Alloy Or Not: Is Alloy Secondary Or Not: Non-secondary Project Solution Capability: graphic design, total solution for projects Application: Offi... -

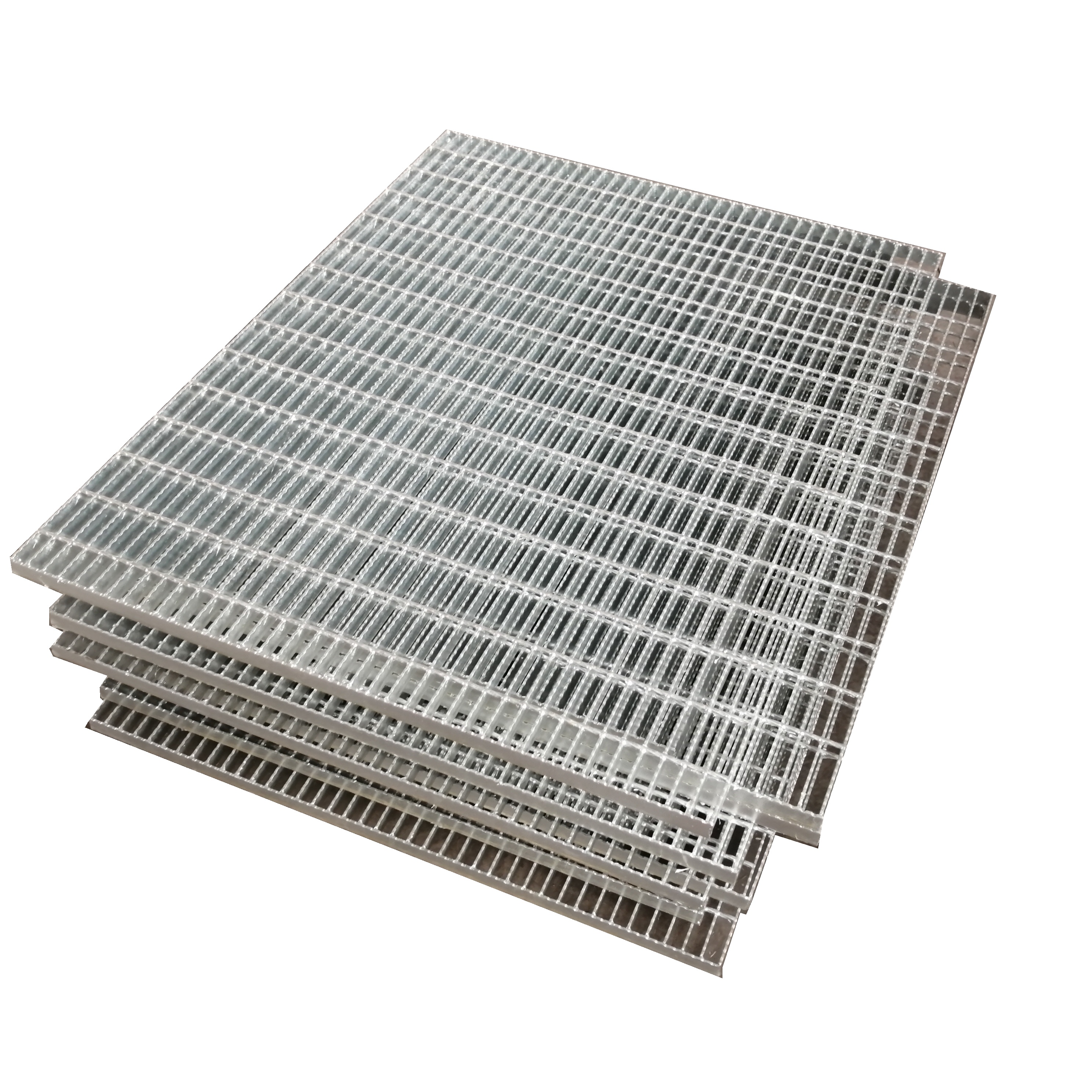

Deck Platform Floor Bar Grating Drain Sistem Metal Steel For Building

Overview Quick Details Warranty: 1 Year After-sale Service: Online technical support, Return and Replacement Alloy Or Not: Is Alloy Secondary Or Not: Non-secondary Project Solution Capability: graphic design, total solution for projects Application: Offi... -

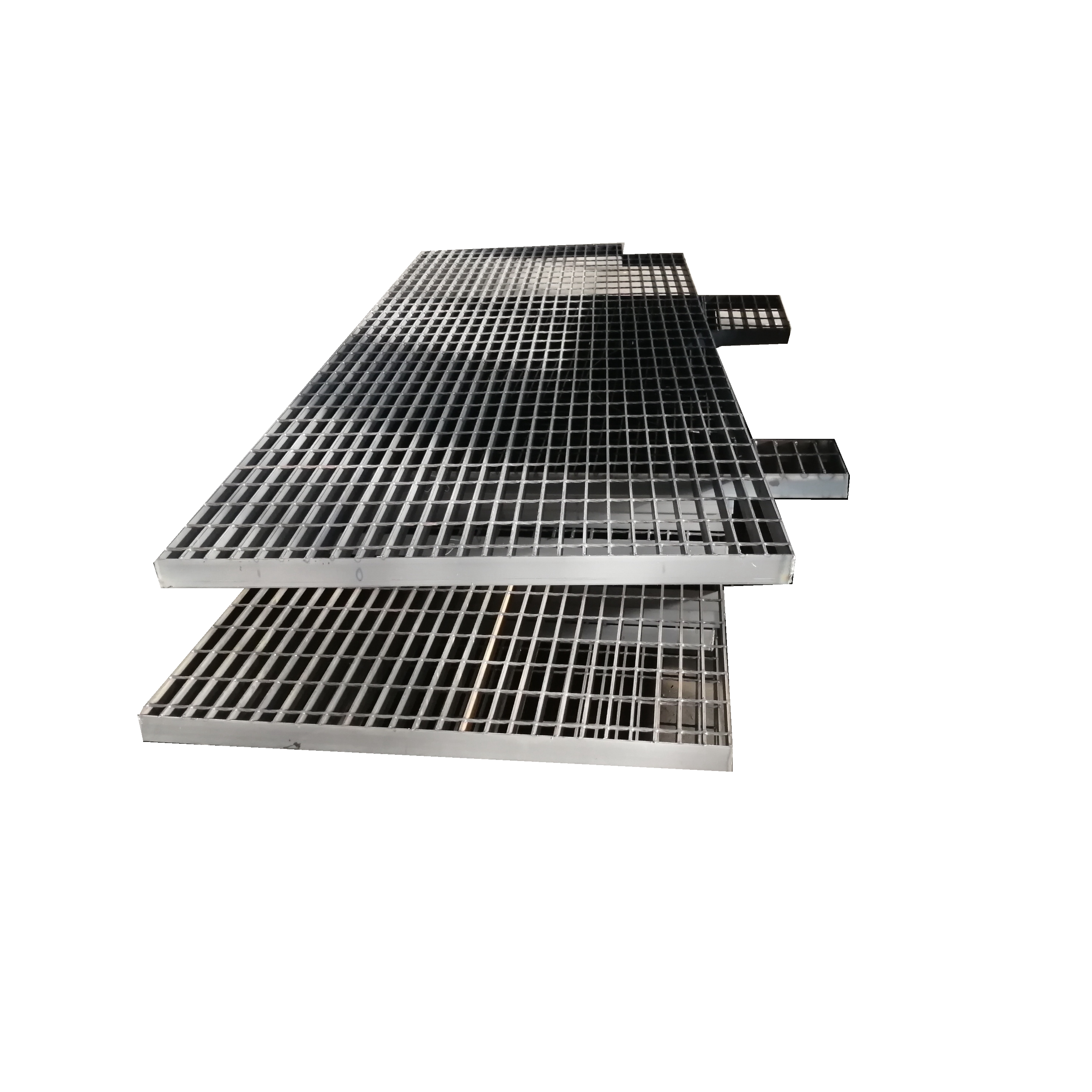

Metal Grates Snow Floor Decking Sheet Steel Grid Plate

Overview Quick Details Warranty: 1 Year After-sale Service: Online technical support, Return and Replacement Alloy Or Not: Is Alloy Secondary Or Not: Non-secondary Project Solution Capability: graphic design, total solution for projects Application: Office Building Design Style: Modern Place of Origin: Shandong, China Brand Name: XianTang Model Number: plain style steel grating 253 Product name: Steel Grating Surface treatment: Hot galvanized... -

Outdoor Walkway Hot Dip Galvanisers Steel Bar Grating For Manhole Cover

Plug-in steel grating classification

According to different insertion methods and different insertion angles, it can be divided into ordinary plug-in steel grating, integral plug-in steel grating, sun shade plug-in steel grating, etc.

1、Ordinary plug-in steel grating: It means that the flat steel that acts as a cross bar is smaller than the load-bearing flat steel. This not only has the characteristics of plugging the steel grating, but also can save costs.

2、Integral plug-in steel grating: its bearing flat steel and cross-bar flat steel have the same height, and the groove depth is 1/2 of the bearing flat steel

3、Sunshade type plug-in steel grating plate: its bearing flat steel is chute of 30 degree or 45 degree, and the cross bar flat steel is slotted and press-locked to form

Generally speaking, the processing height of the production plug-in steel grating is 100mm, and the length of the steel grating is usually less than 2000mm

Features of Plug-in Steel Grating Plate

1、Flat steel spacing, insert flat steel spacing specifications are diverse, which can meet the needs of different users

2、The flat steel room adopts a press lock structure, the surface mesh is flat, the design is beautiful, maintenance-free, there is no difference between the front and back and the flat steel bearing direction, and the bearing capacity is stronger.

3、With higher carrying capacity, such as the need to pass the dock of heavy vehicles, the ditch cover of the mining area.

4、Anti-corrosion, impact resistance, maintenance-free, long service life

-

I 32 Stainless Galvanized Mild Standard Prices Weight Size Steel Grating

Overview Quick Details Warranty: 1 Year After-sale Service: Online technical support, Return and Replacement Project Solution Capability: graphic design, total solution for projects Place of Origin: Shandong, China Brand Name: XianTang Model Number: plain style steel grating 253 Product name: Steel Grating Surface treatment: Hot galvanized ,Paint,Untreated (black/slef color) Weld way: Automatic pressure resistance welding Usage: Industrial platform, ...